Hone of the day.

- Thread starter JamieM

- Start date

Steve56

Forum GOD!

Honed up a couple of new arrivals recently, a Cape 500 Swedish Steel which makes me a pair of these, and a singing 15/16 Gen 1 Filarmonica Muleta.

One interesting thing is that I am trying out a 2-stone synthetic progression before the finisher (old ugly in this case), a Shapton Glass 2k HR, my normal bevel setter, followed by a Shapton Glass 6k HC. This progression has worked very well so far, and every finisher that I’ve used with it has performed no differently than a progression with more steps. I still use a Shapton Glass 4k HR for light bevel work on full hollows when there’s no need to go back to the bevel setter.

One interesting thing is that I am trying out a 2-stone synthetic progression before the finisher (old ugly in this case), a Shapton Glass 2k HR, my normal bevel setter, followed by a Shapton Glass 6k HC. This progression has worked very well so far, and every finisher that I’ve used with it has performed no differently than a progression with more steps. I still use a Shapton Glass 4k HR for light bevel work on full hollows when there’s no need to go back to the bevel setter.

Zwilling

Kamisori shaver

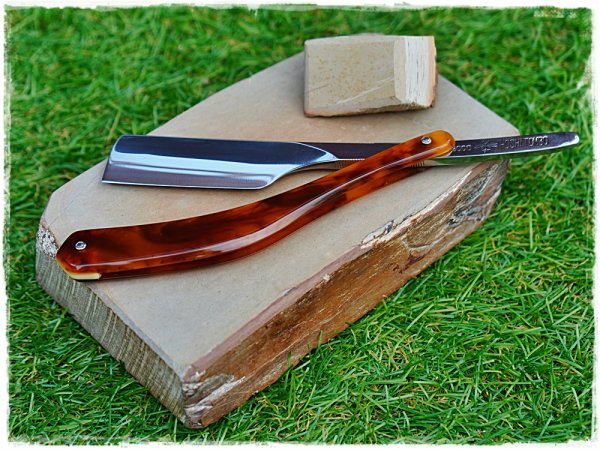

Wow Jamie, that kamisori looks like it is almost honed away! Did the other side still have a concave?This one needed a bit of work the edge was a mess plus the toe has a few nasty chips, all sorted back out tomorrow.

View attachment 72318

JamieM

Extreme sharpness is ephemeral!

Wow Jamie, that kamisori looks like it is almost honed away! Did the other side still have a concave?

The Omote is almost gone, a very old and very well used Kamisori, having said that it certainly took a great edge.

Zwilling

Kamisori shaver

The ones that look like that always do, don’t they?The Omote is almost gone, a very old and very well used Kamisori, having said that it certainly took a great edge.

JamieM

Extreme sharpness is ephemeral!

Todays honing was both a rewarding interesting learning curve and experiment, this is my first foray into the world of Japanese naturals, well let us start at the beginning firstly I'm a big fan of synthetic stones Chosera Naniwa and my lovely Suehiro Gokumyo 20K, the Japanese stone in question was gifted to me by a good friend from Japan, he gave me the low down on the stone before he sent it, he said the Stone was a Nakayama +5 very hard and a very fine finisher, also included was matching Nagura rubbing stone, well here we go let's get the show on the road, firstly I had to choose the razor to test how good this stone is, razor chosen Hoshi Tombo 8000 quarter hollow 13/16, the razor as always been a top-quality shaver, so next thing to do was totally kill the edge on the corner of my Chosera 5K, next step reset the bevel on the 5K and finish on my Snow White 8K, firstly I lightly lapped the Nakayama splashed some water then proceded to create some slurry using the Nagura, I always tape my own razors this was no different, the first few passes I could instantly tell the stone was very fine, I put in about 100 passes then I started to dilute the slurry down, another 50 passes I now washed all slurry off the stone then checked the razors edge under the loupe, the polished bevel looks great, ownwards we go with a clean wet stone no slurry only water another 50 passes, finished edge looks very nice stropped the edge looks and feels great, the ultimate test is yet to come the shave, having said that I'm pretty confident I nailed it.

Steve56

Forum GOD!

I bought another stubtail, Warburton Lisbon Cast Steel. Lummus’ comments would seem to date it to between 1772 (when they began marking ‘cast steel’) and around 1800 when ‘Lisbon’ changed to ‘Warburton’. Any comments on age would certainly be welcome!

This razor is not as cosmetically nice shape as my Shepherd, but like the Shepherd it has very little wear on it. It’s a candidate for a better restoration than I’m capable of, so I decided to hone it and give ‘er a shave (tomorrow most likely). I wanted to use tape on the spine because these old razors just don’t look right with shiny spines, so the first job was to measure the bevel angle at the heel and widest portion near the toe. It turned out that the angle is a very normal 17.7 degrees at the heel and 18.2 degrees at the toe, so I went with 1 layer of 1 mil Kapton (2.7 mil total) and added about 1/2 a degree to the existing angle.

The edge had 3 really small chips, some light devil’s spit, and there wasn’t any bevel so a Shapton Glass 500 did the honors of removing the chips and DS, and forming new bevels. The first thing that I noticed is that the steel is hard! Even the Glass Stones cut it fairly slowly, but progress was steady so I just used some slurry on the 500 and kept at it. And the steel is very good too, even at 500 grit the edge was straight and even, a sign of good things to come, and they did. Next was a 1k GS and a 2k GS. After the 2k, I did 10 canvas and 20 leather and did HHT to test for bevel set, and it passed very well with a little extra attention to the hollow area at the heel. A razor that will turn out good HHT at 2k is IMO, a really good one.

Next a 4k GS, a butterscotch Nakayama kiita for a pre-finisher though this stone is quite capable of finishing without another step, but I chose a small Nakayama iro from my trip to visit Alex Gilmore in Sonoma, using thin slurry and finishing with 20 clear water strokes. The HHT was silent root in or out, though the hollow area at the heel could use a bit more attention in the last few mm, but that’s a small job for another day.

This razor is not as cosmetically nice shape as my Shepherd, but like the Shepherd it has very little wear on it. It’s a candidate for a better restoration than I’m capable of, so I decided to hone it and give ‘er a shave (tomorrow most likely). I wanted to use tape on the spine because these old razors just don’t look right with shiny spines, so the first job was to measure the bevel angle at the heel and widest portion near the toe. It turned out that the angle is a very normal 17.7 degrees at the heel and 18.2 degrees at the toe, so I went with 1 layer of 1 mil Kapton (2.7 mil total) and added about 1/2 a degree to the existing angle.

The edge had 3 really small chips, some light devil’s spit, and there wasn’t any bevel so a Shapton Glass 500 did the honors of removing the chips and DS, and forming new bevels. The first thing that I noticed is that the steel is hard! Even the Glass Stones cut it fairly slowly, but progress was steady so I just used some slurry on the 500 and kept at it. And the steel is very good too, even at 500 grit the edge was straight and even, a sign of good things to come, and they did. Next was a 1k GS and a 2k GS. After the 2k, I did 10 canvas and 20 leather and did HHT to test for bevel set, and it passed very well with a little extra attention to the hollow area at the heel. A razor that will turn out good HHT at 2k is IMO, a really good one.

Next a 4k GS, a butterscotch Nakayama kiita for a pre-finisher though this stone is quite capable of finishing without another step, but I chose a small Nakayama iro from my trip to visit Alex Gilmore in Sonoma, using thin slurry and finishing with 20 clear water strokes. The HHT was silent root in or out, though the hollow area at the heel could use a bit more attention in the last few mm, but that’s a small job for another day.

BlacknTan

Forum GOD!

This stone was sold to me as "La Nouvelle Vein," I don't know if that's what it is, and neither did he. Oddly enough, it looks like it could be La Nouvelle... it acts like La Nouvelle... slow as molasses going uphill in January finishing on plain water. But, it delivers a memorable shave if one is willing to put in the time on the stone.

Here's today's Max Sprecher Special on the coticule in question...

Here's today's Max Sprecher Special on the coticule in question...